Last Updated on July 27, 2023

Welcome to our article on how to make a spring-loaded arm! In this guide, we will walk you through the process of creating your very own spring-loaded arm, a versatile mechanical device that can be used for various applications. Whether you’re a high school student looking to explore the world of engineering or simply someone with a curiosity for DIY projects, this article is for you.

Understanding the concept of a spring-loaded arm

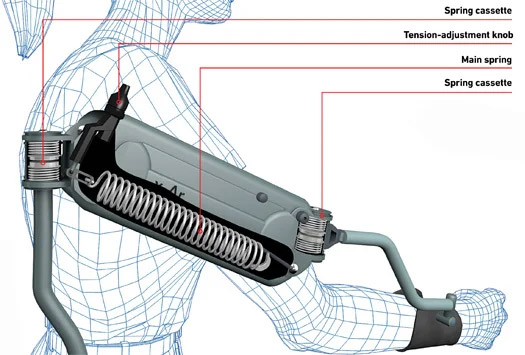

A spring-loaded arm is a mechanical device that uses the force of a spring to create movement or apply pressure. It is commonly used in various applications such as robotics, engineering, and even in everyday objects like door hinges. Understanding the concept of a spring-loaded arm is essential before attempting to build or work with one. Here are some key points to consider:

- A spring-loaded arm consists of a spring, a lever or arm, and a pivot point.

- The spring provides the force needed to move the arm or apply pressure.

- The lever or arm amplifies the force of the spring and transfers it to the desired object or mechanism.

- The pivot point allows the arm to rotate or move in a controlled manner.

By understanding these basic components and how they work together, you can effectively design and build a spring-loaded arm for your specific needs.

Gathering the necessary materials and tools

Before you can start assembling your spring-loaded arm, it’s important to gather all the necessary materials and tools. This will ensure that you have everything you need to complete the project without any interruptions. Here is a list of the items you will need:

- Spring: Choose a spring that is strong enough to provide the desired amount of tension for your arm. Make sure it is the appropriate size for your project.

- Arm components: You will need various components to build the arm, such as rods, brackets, and joints. These can be made from metal or plastic, depending on your preference.

- Fasteners: Use screws, nuts, and bolts to secure the different parts of the arm together. Make sure they are the correct size and type for your project.

- Tools: You will need a variety of tools to assemble the arm, including a screwdriver, wrench, pliers, and a drill. Make sure you have the appropriate tools for the job.

Once you have gathered all the necessary materials and tools, you will be ready to start assembling your spring-loaded arm.

Step-by-step instructions for assembling the spring-loaded arm

Now that you have gathered all the necessary materials and tools, it’s time to start assembling your spring-loaded arm. Follow these step-by-step instructions to ensure a successful build:

- Begin by attaching the base plate to a sturdy surface using screws or adhesive. Make sure it is securely fastened.

- Next, take the main arm and attach it to the base plate using a hinge. This will allow the arm to move up and down.

- Attach the spring to the top of the main arm using a hook or clamp. Make sure the spring is securely fastened and has enough tension to provide the desired force.

- Attach the secondary arm to the main arm using another hinge. This will allow the secondary arm to move independently.

- Attach the gripping mechanism to the end of the secondary arm. This can be a claw, a magnet, or any other device that suits your needs.

- Test the arm by manually pushing it down and releasing it. It should spring back up and the gripping mechanism should open and close smoothly.

- If the arm is not properly balanced, adjust the tension of the spring or the position of the gripping mechanism until it functions correctly.

- Once you are satisfied with the arm’s performance, secure all the components with screws or bolts to ensure they stay in place.

Remember to refer to the specific instructions provided with your materials and tools, as they may vary slightly from these general guidelines. Take your time and double-check each step to ensure a safe and functional spring-loaded arm.

Tips for ensuring the arm is properly balanced and functional

- Ensure that the spring used is appropriate for the weight and size of the arm. A spring that is too weak will not provide enough force, while a spring that is too strong may cause the arm to be too difficult to move.

- Make sure that the pivot point of the arm is well lubricated to allow for smooth movement. Use a high-quality lubricant that is suitable for mechanical devices.

- Check that all the components of the arm are securely fastened together. Loose screws or bolts can cause the arm to wobble or become unstable.

- Test the arm’s range of motion before finalizing the assembly. Make any necessary adjustments to ensure that the arm can move freely and smoothly without any obstructions.

- Consider adding a counterweight to the opposite end of the arm to help balance the weight and improve stability. This can be achieved by attaching a weight or using a heavier material for the opposite end.

6. Testing and troubleshooting the spring-loaded arm

Once you have assembled your spring-loaded arm, it is important to test it to ensure it is functioning properly. Here are some steps you can follow to test and troubleshoot your arm:

- Attach the arm to a sturdy base or platform.

- Activate the spring mechanism and observe the arm’s movement.

- Check if the arm extends and retracts smoothly.

- Ensure that the arm is able to hold and release objects effectively.

- Test the arm’s range of motion and adjust the tension of the spring if necessary.

- Inspect all the connections and joints to make sure they are secure.

- If the arm is not functioning properly, troubleshoot by checking for any loose or damaged parts.

- Make any necessary adjustments or repairs to fix the issue.

Remember, troubleshooting may require some trial and error, so be patient and persistent in finding the solution. If you are unable to resolve the issue on your own, consider seeking assistance from a more experienced individual or consulting online resources.

Exploring different applications for a spring-loaded arm

Once you have successfully assembled your spring-loaded arm, you may be wondering about the various ways in which you can utilize this mechanical device. The versatility of a spring-loaded arm allows for a wide range of applications, making it a valuable tool in many different fields.

One common application of a spring-loaded arm is in the field of robotics. The arm can be used to create robotic limbs that mimic human movements, allowing for more precise and controlled actions. This can be particularly useful in industries such as manufacturing and healthcare, where delicate tasks need to be performed with accuracy.

Another application of a spring-loaded arm is in the field of sports and fitness. The arm can be incorporated into training equipment, such as resistance bands or exercise machines, to provide varying levels of resistance and challenge. This can help athletes and fitness enthusiasts improve their strength and endurance.

Additionally, a spring-loaded arm can be used in the field of engineering and construction. It can be integrated into machinery and equipment to assist with lifting, pushing, or pulling heavy objects. This can increase efficiency and reduce the risk of injury for workers.

Overall, the possibilities are endless when it comes to the applications of a spring-loaded arm. Its versatility and functionality make it a valuable tool in various industries and fields.

Safety Precautions to Consider When Working with Springs and Mechanical Devices

When working with springs and mechanical devices, it is important to prioritize safety to prevent accidents and injuries. Here are some safety precautions to consider:

1. Wear protective gear:

Always wear safety goggles, gloves, and appropriate clothing to protect yourself from any potential hazards.

2. Handle springs with care:

Be cautious when handling springs as they can be under tension and may snap back unexpectedly. Use tools or gloves to handle them and avoid placing your fingers near the ends.

3. Follow instructions carefully:

Read and understand the instructions provided for assembling and using the spring-loaded arm. Follow them step by step to ensure proper installation and operation.

4. Keep a safe distance:

When testing or operating the spring-loaded arm, maintain a safe distance from the arm and any potential hazards. This will help prevent any accidents or injuries.

5. Secure the arm properly:

Make sure the spring-loaded arm is securely attached to its base or mounting surface. This will prevent it from falling or causing any unintended movements.

6. Regular maintenance:

Perform regular maintenance checks on the spring-loaded arm to ensure it is in good working condition. Inspect for any signs of wear or damage and replace any worn-out parts.

By following these safety precautions, you can safely work with springs and mechanical devices, ensuring a successful and accident-free experience with your spring-loaded arm.

Maintenance and Care for a Spring-Loaded Arm

Once you have successfully built and tested your spring-loaded arm, it is important to understand how to properly maintain and care for it. By following these guidelines, you can ensure that your arm remains in good working condition for a long time.

1. Regular Cleaning: Keep your spring-loaded arm clean by wiping it down with a soft cloth after each use. This will help remove any dirt or debris that may have accumulated on the surface.

2. Lubrication: Apply a small amount of lubricant to the moving parts of the arm, such as the joints and springs. This will help reduce friction and ensure smooth operation.

3. Inspection: Regularly inspect the arm for any signs of wear or damage. Check the springs, hinges, and connections to make sure they are secure and functioning properly.

4. Storage: When not in use, store your spring-loaded arm in a clean and dry environment. Avoid exposing it to extreme temperatures or moisture, as this can cause damage.

5. Professional Maintenance: If you notice any significant issues with your arm or are unsure about how to properly maintain it, seek the assistance of a professional. They can provide expert advice and perform any necessary repairs.

By following these maintenance and care guidelines, you can ensure that your spring-loaded arm remains in optimal condition and continues to serve its purpose effectively.

Wrapping it Up: The Power of a Spring-Loaded Arm

After delving into the intricacies of creating a spring-loaded arm, it is clear that this mechanical marvel holds immense potential. By understanding the concept, gathering the necessary materials, and following step-by-step instructions, anyone can assemble their own spring-loaded arm.

Proper balance and functionality are crucial aspects to consider during the assembly process. Ensuring that the arm is well-balanced will optimize its performance and prevent any mishaps. Additionally, regular testing and troubleshooting will help identify and rectify any issues that may arise.

Furthermore, the versatility of a spring-loaded arm cannot be overlooked. Its applications span across various fields, from robotics to engineering, making it a valuable tool for countless projects.

However, it is important to prioritize safety when working with springs and mechanical devices. Adhering to safety precautions will minimize the risk of accidents and injuries.

Lastly, maintaining and caring for your spring-loaded arm will prolong its lifespan and ensure its continued functionality. Regular inspections and lubrication will keep it in optimal condition.

In conclusion, the creation and utilization of a spring-loaded arm is a fascinating endeavor. With the right knowledge and precautions, this mechanical wonder can open doors to endless possibilities.

Learn how to make a spring-loaded arm with this step-by-step guide. Discover its applications and safety precautions.

About The Author

Alison Sowle is the typical tv guru. With a social media evangelist background, she knows how to get her message out there. However, she's also an introvert at heart and loves nothing more than writing for hours on end. She's a passionate creator who takes great joy in learning about new cultures - especially when it comes to beer!