Last Updated on September 17, 2022

If you’ve ever wondered how to make a spinnaker, then you’ve come to the right place. This article will show you how to make a spinnaker sock – from making the sleeve to stringing it up. From there, you can douse and store it in a bag. But before you do that, you should know the importance of securing the sleeve properly.

Making a spinnaker sleeve

If you are a novice to spinnakers, you should learn how to make a spinnaker sock. Spinnaker sleeve patterns have become incredibly popular in recent years and a spinnaker sock is an excellent way to learn the basics. These patterns are based on the original design by Eric Tabarly, which is a simple steel ring with a number of tiny points. A spinnaker sleeve should be oval-shaped, which is easier to pull through a hatch.

When making a spinnaker sock, you need to keep in mind that the length of the sock is smaller than the length of the leech of the sail. This allows for a simple operation and ensures that you do not tangle the line with the sail. This design is easy to make and is a popular choice for many sailors. If you plan on using your sock for several years, it is important to consider its size and durability.

You’ll need to make a sleeve made of lightweight material that doesn’t cause too much friction. Ideally, the fabric won’t bleed color onto the spinnaker. The sleeve should be long enough to attach a control line block, as well as long enough to lead through a snatch-block and cleat. If you’re a novice, consider using a control line that is not too thick.

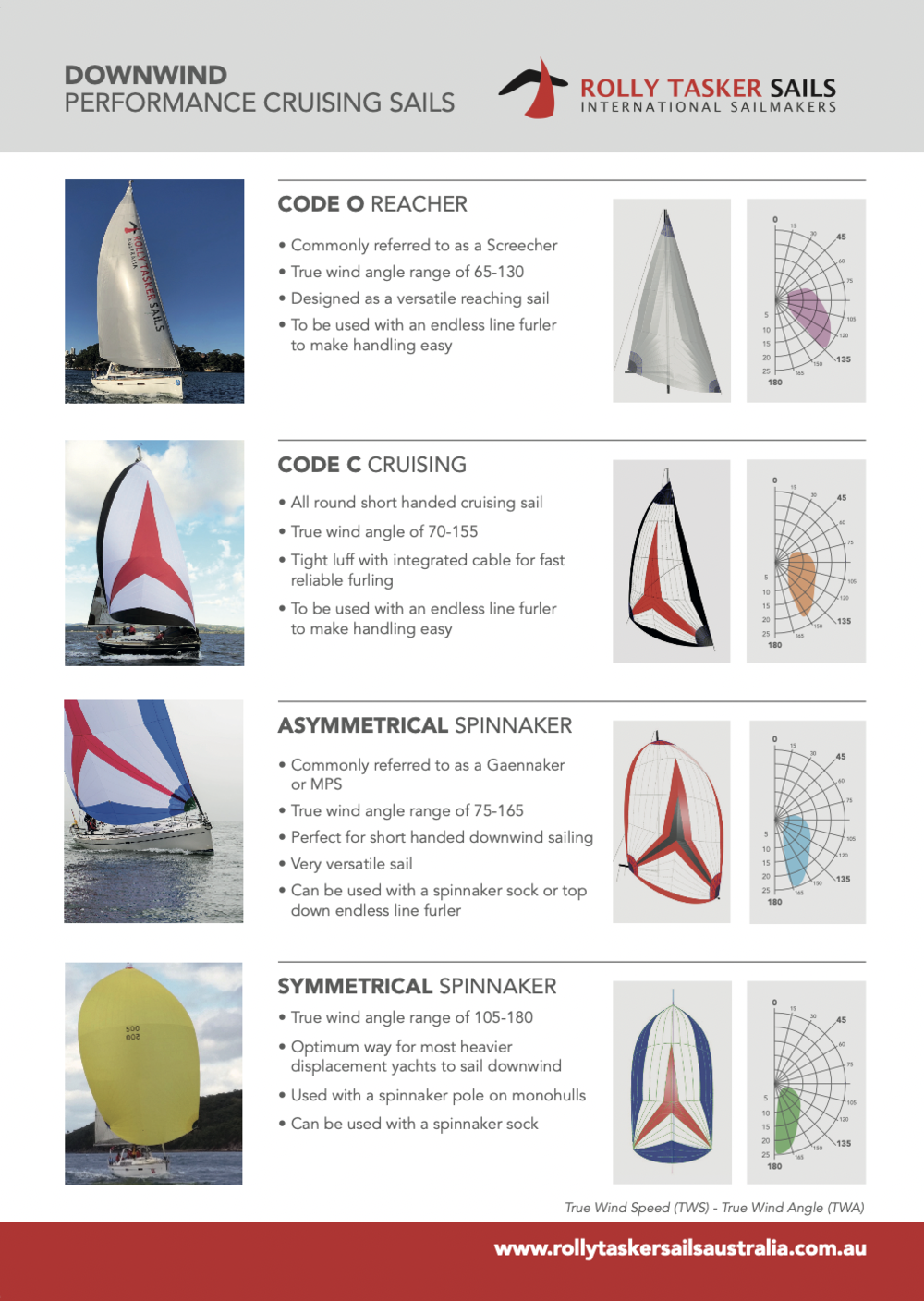

A spinnaker sock can be made out of many different materials. The material used is usually polyester, which has excellent heat-resistant properties. This material is also breathable, which makes it ideal for a spinnaker sock. Once you’ve got the materials ready, the sock can be made as a whole or as individual parts. In any case, a spinnaker sock is a very important sail for catamarans.

To make a spinnaker sock, you’ll need a couple of tools and a good pair of hands. First, you need a snuffer. A snuffer is a long tube of nylon cloth that works by squeezing the spinnaker closed. It attaches between the halyard and the sail head. A snuffer contains a hard ring on the bottom, which acts as a funnel to squeeze the spinnaker. Next, you’ll need a line to rig the snuffer. After that, simply pull the snuffer over the sail.

To attach the spinnaker sleeve, you must first make the Ronstan block. This block is attached to the spinnaker with a metal strap that snaps into place. Often, this is difficult to do and will pop the becket out of the block. If you don’t have a spinnaker sleeve, you’ll have trouble securing the block in its proper position with whipping.

Stringing up the sleeve

To string up a spinnaker sock, you must first prepare the sail on the front deck of your sailboat. The wind must be behind you and the apparent wind should be light. Make sure that the sock does not fall into the water or overboard. The classic spinnaker is rigged to go downwind, but a seasoned sailor can also rig it to sail upwind.

Before stringing the sleeve of the spinnaker, you must remove the collar of the spinnaker. If you’re releasing more than one line at a time, the sleeve will “waddle” and may be thrown off the boat. This is not an ecological or economical solution, and you could end up with a spinning spinnaker that slides off the deck.

To string the sleeve of a sail, you must tie two different lines, the lighter one is tied into the sleeve and the heavier line is attached to the upper half. The lighter line is tied to the heavier line, which is attached to the mouth fabrication, which is a fairly heavy fiberglass structure. You can add a bit of oxyalic acid or baking soda to the line to get rid of the rust.

You must remember that the sail must be furled before it can be hoisted. The sock must be loaded into the spinnaker sleeve one by one, with the genoa sail being the last one to be put on. It must be properly rigged in order to avoid getting caught behind the spreaders. Once the sleeve has been rigged properly, the sail should be stored in accordion fashion in the bag.

Basically, the sleeve control line has two parts. One side leads the spinnaker sleeve while the other leads the control line to hoist the spinnaker. This control line is made of two different lines, one that controls the up and down lines and the other to raise and lower the sleeve.

After you have successfully attached the control line to the spinnaker sleeve, you must string the Ronstan block into the sleeve using the metal strap. A mistake in this step will pop out the becket. Another mistake is stuffing the spinnaker sleeve into a locker. In addition, the control line may work its way out of the secondary sleeve.

Dousing the sleeve

Dousing the sleeve of your spinnaker is one of the most difficult sail handling tasks, especially when you’re sailing shorthanded. The process can be much easier with spinnaker socks. The sleeve is a nylon tube with a smooth, fiberglass reinforced plastic ring in the center that allows a single sailor to gather the spinnaker sail. The nylon tube is custom designed to protect the spinnaker and not create any problems for the sail.

ATN offers an economical spinnaker sock designed to fit sails up to 40 feet long. This nylon sleeve has an internal halyard sleeve that prevents dousing line from tangling. This sleeve is self-contained and ships directly from the manufacturer. You only need your spinnaker halyard and regular socks to raise and lower the sail.

Another benefit of SnufferPlus is the 20-minute video that comes with the sleeve. This DVD demonstrates how to install the sleeve and set spinnaker sleeves. It also shows how to douse the sleeve of a spinnaker. The video is available from ATN and is a valuable tool for anyone wanting to get started.

About The Author

Mindy Vu is a part time shoe model and professional mum. She loves to cook and has been proclaimed the best cook in the world by her friends and family. She adores her pet dog Twinkie, and is happily married to her books.