Last Updated on September 17, 2022

Installing a case drain on your hydraulic system can prevent contaminants from moving from the hydraulic motor to the reservoir. Additionally, these drains prevent oil from building up on the outer seal. Listed below are a few steps you should follow to install a case drain. You can also install a shuttle valve, which will send the oil back through the return line instead. Once you’ve installed a case drain, you can begin replacing it.

Case drains prevent contaminants from travelling from the hydraulic motor to the reservoir

A case drain is a low pressure hydraulic line that travels from the final drive motor to the hydraulic fluid reservoir. Its main purpose is to carry away any internal leaks of hydraulic fluid from the motor. Case drain lines are a common feature of many hydraulic machines, and they are one of the most common causes of catastrophic failure of final drive motors. Case drain filters prevent contaminants from travelling from the hydraulic motor to the reservoir, and are an essential part of the overall health of your equipment. When these filters become clogged, it can have disastrous consequences for your final drive.

When repairing a hydraulic motor, you should always clean the reservoir and check the case drain line. This line must be free of debris to prevent excessive pressure in the case. Any blockage in the case drain line can cause the case to build up and damage the pump. Debris may lodge inside conductors or fittings, restricting the case flow and resulting in a high pressure. Do not use compressed air to check for blockages. In addition to cleaning the reservoir, it is also important to perform a reservoir clean-out. This is necessary to remove heavy contamination and to maintain a longer life for your tools.

A case drain is a small line that connects the hydraulic fluid reservoir to the final drive motor of an excavator. It is responsible for transporting internal leaks away from the hydraulic motor. A clogged case drain can cause catastrophic failure of the drive motor and result in catastrophic damage to your machine. So, make sure you check the filter on a regular basis! It can save you thousands of dollars in repairs!

Contaminated hydraulic systems are very common. It is especially common to work in mobile hydraulic systems and servicing machines. In such an environment, the disconnected hydraulic parts may scrape dirt on the ground. This can result in a contaminated hydraulic system. It is important to clean this system periodically so that contaminants do not travel to the reservoir. If you do not clean the reservoir, the contamination will continue to circulate in the system.

They prevent oil from building up against the outer seal

The case drain is a crucial component of the hydraulic system. It prevents oil from building up against the outer seal and prolongs the life of the hydraulic system. If you don’t install a case drain, you will likely experience shaft seal leaks that will cause your entire system to fail. Installing a case drain line is easy but can be tedious. Installing a case drain will ensure that you don’t have to worry about shaft seal leaks again in the future.

They can be removed and disassembled

To maintain the integrity of your hydraulic system, you should clean case drains at least once a year to ensure that they function properly. Filters are made from sintered bronze, which looks like a solid piece of metal, but is actually composed of thousands of tiny bronze spheres that are sintered together. This process gives the bronze the strength needed to withstand the high temperatures of the hydraulic fluid, while still being dense enough to prevent the contamination of your hydraulic system.

The most challenging part of cleaning your drains is getting small objects out of them. These can be very difficult to remove, unless you know a lot about plumbing. Even then, you’ll need a strong set of hands to get the small objects out. In any case, you’ll likely need a professional plumber for this job, unless you have some knowledge of plumbing or know how to use tools safely.

They can be replaced

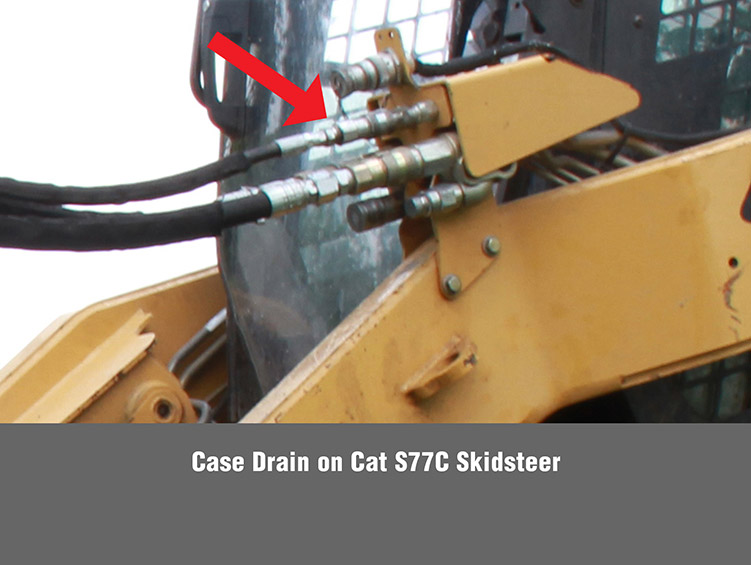

A case drain is a filter positioned in the final drive of a hydraulic system. It maintains the cleanliness of the fluid, depending on the operating pressure and internal clearances of various components. If the case drain filter becomes blocked, the skid steer can experience mechanical and hydraulic problems. It may even blow a seal, letting hydraulic fluid or lubricant leak out and contaminating the skid steer. Replacing a case drain is a relatively inexpensive repair when compared to replacing the entire final drive.

About The Author

Mindy Vu is a part time shoe model and professional mum. She loves to cook and has been proclaimed the best cook in the world by her friends and family. She adores her pet dog Twinkie, and is happily married to her books.