Last Updated on July 27, 2023

Welcome to this article on how to find cross sectional area in Solidworks. Whether you are a student or a professional in the field of engineering or design, understanding cross sectional area is essential for accurate measurements and design analysis. In this article, we will explore the concept of cross sectional area and its significance in Solidworks. We will also learn how to use the Measure Tool in Solidworks to select the appropriate plane for measurement and define the cross sectional area. Additionally, we will discuss the process of calculating the cross sectional area and checking the accuracy of the measurement. Finally, we will explore how to apply the cross sectional area in Solidworks and utilize it for design analysis. So, let’s dive in and enhance our knowledge of cross sectional area in Solidworks!

Understanding Cross Sectional Area

Understanding cross sectional area is essential in various fields such as engineering, architecture, and design. It refers to the area of a two-dimensional shape that is obtained when a solid object is cut perpendicular to its axis. This measurement is crucial in determining the strength, stability, and functionality of a structure or component.

To enhance your understanding of cross sectional area, consider the following points:

- Definition: Cross sectional area is the area of the shape that is exposed when a solid object is cut perpendicular to its axis.

- Importance: It helps in analyzing the structural integrity and performance of a component or structure.

- Measurement: Cross sectional area can be measured using various tools and software, such as the Measure tool in Solidworks.

- Accuracy: It is crucial to ensure the accuracy of the measurement by selecting the appropriate plane and defining the cross sectional area correctly.

- Application: The cross sectional area obtained can be applied in Solidworks for design analysis and other engineering purposes.

By understanding cross sectional area and its significance, you can effectively analyze and design structures with precision and accuracy.

Using the Measure Tool in Solidworks

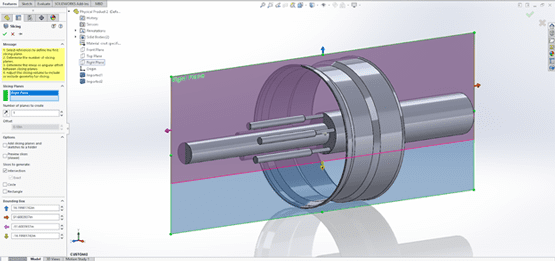

In order to find the cross sectional area in Solidworks, you will need to utilize the Measure tool. This tool allows you to measure various dimensions and properties of your model, including the cross sectional area. To access the Measure tool, go to the Evaluate tab in the Command Manager and click on the Measure tool icon.

Once you have opened the Measure tool, you will need to select the appropriate plane for measurement. The plane you choose will depend on the specific part or feature of your model that you want to measure. Solidworks offers a variety of plane options, such as the Front Plane, Top Plane, and Right Plane, among others. Select the plane that best aligns with the part or feature you are interested in.

Selecting the Appropriate Plane for Measurement

When using the Measure Tool in Solidworks to find the cross sectional area of a part, it is crucial to select the appropriate plane for measurement. The plane you choose will determine the accuracy of your measurement and the reliability of the data you obtain.

First, you need to identify the plane that represents the cross section you want to measure. This can be a plane that intersects the part at a specific location or a plane that is parallel to a specific feature of the part.

Once you have identified the plane, you can select it in Solidworks by using the Plane tool. This tool allows you to create a new plane or select an existing plane from the part. Make sure to position the plane in a way that accurately represents the cross section you want to measure.

By selecting the appropriate plane for measurement, you can ensure that your cross sectional area calculations are accurate and reliable. This will enable you to make informed design decisions and optimize your part for its intended application.

Defining the Cross Sectional Area

When working with Solidworks, it is important to accurately define the cross sectional area of a part or object. This measurement is crucial for various design analysis and calculations. Here are some steps to help you define the cross sectional area in Solidworks:

- Identify the plane: Before defining the cross sectional area, you need to select the appropriate plane for measurement. This plane should be perpendicular to the direction in which you want to measure the area.

- Sketch the section: Once the plane is selected, you can sketch the section of the part or object that you want to measure. This can be done using the sketch tools in Solidworks.

- Close the sketch: After sketching the section, make sure to close the sketch by connecting all the lines or curves. This will create a closed shape, which is necessary for calculating the area.

- Calculate the area: With the sketch closed, you can now calculate the cross sectional area using the appropriate tool in Solidworks. This tool will automatically calculate the area based on the sketch you have created.

By following these steps, you can accurately define the cross sectional area in Solidworks, allowing you to perform various design analysis and calculations with precision.

6. Calculating the Cross Sectional Area

Once you have defined the cross sectional area in Solidworks, you can easily calculate it using the Measure tool. Here are the steps to follow:

- Select the Measure tool from the toolbar or go to Tools > Measure.

- Click on the cross section you want to measure.

- The Measure dialog box will appear, displaying the dimensions of the cross section.

- Look for the area value in the dialog box. This is the calculated cross sectional area.

- Take note of the units used for the area measurement.

It is important to note that the accuracy of the calculated cross sectional area depends on the accuracy of the cross section definition. Make sure that you have accurately defined the cross section before calculating its area.

Additionally, keep in mind that the cross sectional area is a two-dimensional measurement and does not take into account the thickness or depth of the object. If you need to calculate the volume or mass of the object, you will need to consider the third dimension as well.

Checking the Accuracy of the Measurement

Once you have calculated the cross sectional area using Solidworks, it is important to check the accuracy of your measurement. This step is crucial to ensure that your design analysis is based on reliable data.

To check the accuracy, you can compare your measurement with known values or theoretical calculations. This will help you identify any discrepancies or errors in your measurement process.

Additionally, you can use the Measure Tool in Solidworks to verify the accuracy of your measurement. This tool allows you to measure different dimensions and distances within your model, providing you with a comprehensive analysis of your design.

By checking the accuracy of your measurement, you can have confidence in the cross sectional area value you have obtained. This will enable you to make informed decisions during the design analysis process and ensure the success of your project.

Applying the Cross Sectional Area in Solidworks

Once you have calculated the cross sectional area of your object using Solidworks, you can apply this information in various ways to enhance your design process. One of the main applications of the cross sectional area is in stress analysis. By knowing the cross sectional area, you can determine the amount of stress that the object can withstand before it deforms or fails.

Additionally, the cross sectional area can be used to calculate the moment of inertia of the object. The moment of inertia is a measure of an object’s resistance to changes in its rotational motion. By knowing the moment of inertia, you can analyze the object’s stability and predict how it will behave under different loading conditions.

Furthermore, the cross sectional area can be utilized in simulations to predict the behavior of the object in different scenarios. For example, if you are designing a bridge, you can simulate the effect of different loads on the structure by applying the cross sectional area in the simulation.

In conclusion, the cross sectional area obtained through Solidworks is a valuable piece of information that can be applied in various ways to enhance the design analysis process. By utilizing this data, engineers and designers can make informed decisions and optimize their designs for maximum performance and efficiency.

Utilizing the Cross Sectional Area for Design Analysis

Once the cross sectional area has been calculated using Solidworks, it can be utilized for design analysis purposes. The cross sectional area provides valuable information about the geometry of a part or component, which can be used to assess its structural integrity and performance.

One of the main applications of the cross sectional area is in stress analysis. By knowing the cross sectional area of a part, engineers can determine the amount of stress that it can withstand before failure. This information is crucial in designing safe and reliable structures.

Additionally, the cross sectional area can be used to analyze the flow of fluids through a component. By calculating the cross sectional area of a pipe or channel, engineers can determine the flow rate and pressure drop across the component. This is important in designing efficient fluid systems.

Furthermore, the cross sectional area can be used to analyze the thermal properties of a part. By knowing the cross sectional area, engineers can calculate the heat transfer rate and temperature distribution within a component. This is essential in designing effective cooling systems.

In conclusion, the cross sectional area calculated in Solidworks is a valuable tool for design analysis. It provides crucial information about the geometry of a part, which can be used to assess its structural integrity, fluid flow characteristics, and thermal properties. By utilizing the cross sectional area, engineers can design safer, more efficient, and more reliable components and systems.

Wrapping it Up: The Importance of Cross Sectional Area in Solidworks

Throughout this article, we have explored the concept of cross sectional area and its significance in Solidworks. We have learned how to use the Measure Tool to accurately determine the cross sectional area of a solid object, and how to select the appropriate plane for measurement. By defining and calculating the cross sectional area, we can obtain valuable information for design analysis and make informed decisions in our Solidworks projects.

Understanding the cross sectional area allows us to assess the strength, stability, and performance of our designs. It provides us with crucial data that can be used to optimize our models and ensure their functionality. By applying the cross sectional area in Solidworks, we can accurately simulate real-world conditions and predict the behavior of our designs.

So, whether you are an engineer, designer, or simply a Solidworks enthusiast, don’t underestimate the power of cross sectional area. It is a fundamental concept that can greatly enhance your design process and lead to more successful outcomes. Embrace the knowledge you have gained in this article and let it guide you towards creating innovative and efficient designs in Solidworks.

Learn how to find the cross sectional area in Solidworks with this step-by-step guide. Improve your design analysis today!

About The Author

Orochi Konya is a student of the web. He has been dabbling in it since he was young, and has become an expert in his own right. He loves all things digital, from making websites to programming to social media. In his spare time, Orochi enjoys indulging in his other passion: music. He loves listening to all kinds of music and often spends hours creating playlists on Spotify. He also enjoys drawing manga and watching anime in his free time. Orochi is a friendly pop-culture guru who is always happy to chat about the latest trends in both Japan and the U.S.