Last Updated on July 27, 2023

Welcome to our article on how to decrease variable costs in manufacturing. In today’s competitive business landscape, it is crucial for manufacturers to find ways to reduce costs without compromising on quality. Variable costs, which fluctuate based on production levels, can have a significant impact on a company’s bottom line. In this article, we will explore various strategies that can help manufacturers identify and analyze their variable costs, streamline production processes, implement lean manufacturing principles, negotiate with suppliers, invest in technology and automation, train and empower employees, and continuously monitor and evaluate their cost-saving efforts. By implementing these strategies, manufacturers can achieve greater efficiency and profitability. So, let’s dive in and discover how to decrease variable costs in manufacturing!

Understanding Variable Costs in Manufacturing

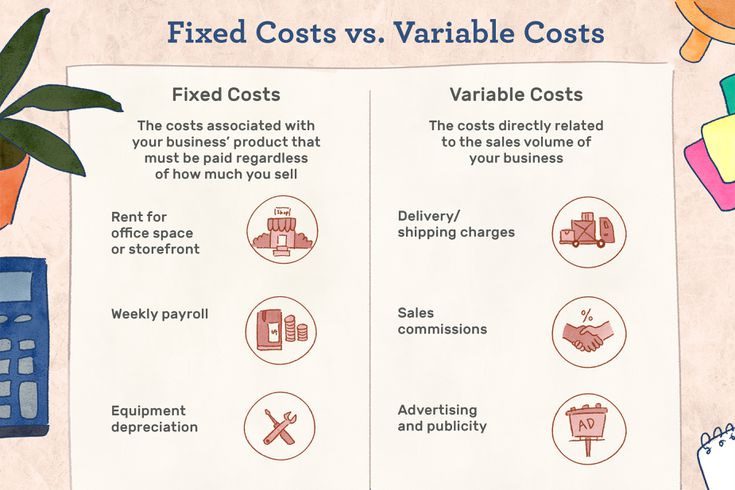

Variable costs are expenses that change in direct proportion to the level of production or sales. In the manufacturing industry, these costs can have a significant impact on the overall profitability of a company. Understanding and effectively managing variable costs is crucial for manufacturers to stay competitive in the market. Here are some key points to consider:

- Variable costs include raw materials, direct labor, and direct overhead expenses.

- These costs can fluctuate based on factors such as production volume, labor rates, and material prices.

- Identifying and analyzing variable costs is essential to determine areas where cost reductions can be made.

- Streamlining production processes can help eliminate waste and reduce variable costs.

- Implementing lean manufacturing principles can improve efficiency and reduce costs.

- Negotiating with suppliers for better pricing and terms can lead to cost savings.

- Investing in technology and automation can increase productivity and reduce labor costs.

- Training and empowering employees can improve their skills and efficiency, leading to cost savings.

- Continuous monitoring and evaluation of variable costs is necessary to identify areas for improvement.

By understanding and effectively managing variable costs, manufacturers can decrease expenses and improve their bottom line.

Analyzing and Identifying Variable Costs

One of the key steps in decreasing variable costs in manufacturing is analyzing and identifying them. Variable costs are expenses that change in direct proportion to the level of production. By understanding and tracking these costs, manufacturers can identify areas where they can make improvements and reduce expenses.

There are several methods that can be used to analyze and identify variable costs. One approach is to conduct a cost-volume-profit analysis, which helps determine the breakeven point and the impact of changes in production volume on costs. This analysis can provide valuable insights into the relationship between production levels and variable costs.

Another method is to use activity-based costing, which involves identifying and allocating costs to specific activities or processes. This allows manufacturers to understand the cost drivers and the activities that contribute the most to variable costs. By focusing on these activities, manufacturers can find ways to optimize processes and reduce expenses.

Additionally, manufacturers can use variance analysis to compare actual costs with budgeted costs. This analysis helps identify any discrepancies and allows manufacturers to take corrective actions to reduce variable costs.

By analyzing and identifying variable costs, manufacturers can gain a better understanding of their cost structure and find opportunities for cost reduction. This is an essential step in the journey towards decreasing variable costs in manufacturing.

Streamlining Production Processes

Streamlining production processes is a crucial step in decreasing variable costs in manufacturing. By optimizing the way products are made, companies can eliminate unnecessary steps, reduce waste, and improve efficiency. This not only saves time but also reduces the amount of resources required, ultimately leading to cost savings.

One way to streamline production processes is by implementing a just-in-time (JIT) manufacturing system. This approach involves producing goods only when they are needed, minimizing inventory and storage costs. By closely monitoring customer demand and adjusting production accordingly, companies can avoid overproduction and reduce the risk of excess inventory.

Another strategy is to implement a cellular manufacturing system, where production is organized into self-contained work cells. This allows for better coordination and communication between workers, reducing the time wasted on unnecessary movement and transportation of materials.

Additionally, companies can invest in automation and robotics to streamline production processes. By automating repetitive tasks, companies can increase productivity and reduce labor costs. However, it is important to carefully evaluate the cost-benefit analysis of automation to ensure that the initial investment is justified by the long-term savings.

Implementing Lean Manufacturing Principles

Implementing lean manufacturing principles can help decrease variable costs in manufacturing by eliminating waste and improving efficiency. Here are some key strategies to consider:

- Identify and eliminate non-value-added activities: Analyze your production processes to identify any steps or activities that do not add value to the final product. Streamline or eliminate these activities to reduce costs.

- Implement just-in-time (JIT) production: JIT production involves producing goods only when they are needed, minimizing inventory and storage costs. This can help reduce variable costs associated with excess inventory.

- Optimize production flow: Ensure that materials, equipment, and information flow smoothly through the production process. Minimize bottlenecks and delays to improve efficiency and reduce costs.

- Implement visual management systems: Use visual cues, such as color-coded labels or signs, to communicate information and instructions clearly. This can help reduce errors and improve productivity.

- Empower employees to identify and solve problems: Encourage employees to actively participate in process improvement initiatives. Provide training and support to help them identify and address inefficiencies.

By implementing these lean manufacturing principles, manufacturers can reduce variable costs and improve overall profitability.

6. Negotiating with Suppliers

One effective way to decrease variable costs in manufacturing is by negotiating with suppliers. By engaging in strategic negotiations, manufacturers can secure better deals and lower prices for raw materials, components, and other supplies. Here are some tips for successful supplier negotiations:

- Research and compare prices: Before entering into negotiations, it is important to research and compare prices from different suppliers. This will give manufacturers a better understanding of the market and help them negotiate from a position of strength.

- Build strong relationships: Developing strong relationships with suppliers can lead to better terms and conditions. By fostering open communication and trust, manufacturers can negotiate for lower prices, longer payment terms, or even exclusive deals.

- Explore alternative suppliers: It is always beneficial to explore alternative suppliers and have multiple options. This gives manufacturers leverage during negotiations and ensures they are getting the best possible deal.

- Consider long-term contracts: Long-term contracts can provide stability and cost savings. By committing to a supplier for an extended period, manufacturers may be able to negotiate lower prices or volume discounts.

- Be prepared to walk away: Sometimes, the best negotiation tactic is to be prepared to walk away if the terms are not favorable. This can show suppliers that manufacturers are serious about getting the best deal and may prompt them to offer more favorable terms.

By effectively negotiating with suppliers, manufacturers can significantly reduce variable costs and improve their bottom line.

Investing in Technology and Automation

Investing in technology and automation is a crucial step in decreasing variable costs in manufacturing. By incorporating advanced machinery and software systems, manufacturers can streamline their production processes and reduce the need for manual labor. This not only increases efficiency but also eliminates the risk of human error, resulting in higher quality products.

One way to invest in technology is by implementing robotics and automated systems. These machines can perform repetitive tasks with precision and speed, reducing the time and cost associated with manual labor. Additionally, manufacturers can utilize software solutions such as enterprise resource planning (ERP) systems to optimize inventory management, production scheduling, and supply chain operations.

Furthermore, investing in technology and automation allows manufacturers to stay competitive in the market. By adopting innovative solutions, companies can improve their production capacity, meet customer demands more efficiently, and reduce lead times. This not only enhances customer satisfaction but also enables manufacturers to lower their variable costs and increase profitability.

Training and Empowering Employees

One crucial aspect of decreasing variable costs in manufacturing is training and empowering employees. By providing comprehensive training programs, employees can develop the necessary skills and knowledge to perform their tasks efficiently. This can lead to increased productivity and reduced waste, ultimately lowering variable costs.

Empowering employees is equally important. When employees feel valued and empowered, they are more likely to take ownership of their work and strive for excellence. This can result in improved quality control, reduced errors, and increased efficiency, all of which contribute to cost savings.

Organizations can empower employees by involving them in decision-making processes, encouraging them to share their ideas and suggestions, and providing opportunities for professional growth and development. Additionally, fostering a positive work culture that promotes teamwork, collaboration, and open communication can further empower employees and enhance their performance.

By investing in training and empowering employees, manufacturers can create a motivated and skilled workforce that is capable of driving down variable costs and improving overall operational efficiency.

Continuous Monitoring and Evaluation

Continuous monitoring and evaluation is a crucial aspect of reducing variable costs in manufacturing. By regularly assessing and analyzing various aspects of the production process, manufacturers can identify areas of inefficiency and take appropriate measures to address them.

One key aspect of continuous monitoring and evaluation is tracking key performance indicators (KPIs). These are specific metrics that measure the performance of different aspects of the manufacturing process, such as production output, quality, and efficiency. By monitoring these KPIs on a regular basis, manufacturers can identify trends and patterns that indicate areas of improvement or potential cost savings.

Another important aspect of continuous monitoring and evaluation is conducting regular audits and inspections. This involves thoroughly examining the production facilities, equipment, and processes to identify any potential issues or areas for improvement. By conducting these audits and inspections on a regular basis, manufacturers can proactively address any issues before they escalate and result in higher variable costs.

In addition, manufacturers should also consider implementing a system for collecting and analyzing feedback from employees, customers, and suppliers. This feedback can provide valuable insights into potential areas for improvement and cost reduction.

Overall, continuous monitoring and evaluation play a crucial role in identifying and addressing inefficiencies and cost drivers in the manufacturing process. By regularly assessing and analyzing various aspects of the production process, manufacturers can make informed decisions and take proactive measures to decrease variable costs.

Wrapping it Up: Strategies for Decreasing Variable Costs in Manufacturing

Throughout this article, we have explored various strategies for decreasing variable costs in manufacturing. By understanding the nature of variable costs and analyzing them effectively, manufacturers can identify areas for improvement. Streamlining production processes and implementing lean manufacturing principles can help eliminate waste and increase efficiency. Negotiating with suppliers can lead to cost savings, while investing in technology and automation can improve productivity and reduce labor costs.

However, it is important to remember that the success of these strategies relies heavily on training and empowering employees. By providing them with the necessary skills and knowledge, manufacturers can ensure that these cost-saving measures are implemented effectively. Continuous monitoring and evaluation are also crucial in order to identify any areas that require further improvement.

By implementing these strategies, manufacturers can decrease their variable costs and improve their overall profitability. It is essential for manufacturers to constantly evaluate and adapt their cost-saving strategies in order to stay competitive in the ever-changing manufacturing industry.

Learn effective strategies to reduce variable costs in manufacturing, including streamlining processes, implementing lean principles, and investing in technology.

About The Author

Zeph Grant is a music fanatic. He loves all types of genres and can often be found discussing the latest album releases with friends. Zeph is also a hardcore content creator, always working on new projects in his spare time. He's an amateur food nerd, and loves knowing all sorts of random facts about food. When it comes to coffee, he's something of an expert - he knows all the best places to get a good cup of joe in town.