Wood has long been admired for its natural beauty and versatility in various applications. However, what if we told you that wood could also be electrified? By using a simple battery charger, you can transform ordinary wood into an electrified wonder, opening up a whole new realm of possibilities. In this article, we will explore the process of electrifying wood, step by step, and discuss its applications. So, let’s dive in!

Understanding the Process

Before we delve into the electrification process, let’s grasp the basic concept. Electricity is the flow of electrons through a conductive material. Some materials, such as metals, are highly conductive, while others, like wood, are not naturally conductive. However, by introducing an electrical charge to wood, we can make it conductive and harness its unique properties.

Materials and Tools Required

To electrify wood, you’ll need a few essential materials and tools. Here’s what you’ll need:

- A battery charger: Choose a low voltage charger suitable for this application.

- Wood: Select a piece of wood that you wish to electrify. Experiment with different types of wood for varying effects.

- Alligator clips: These clips will help connect the wood to the battery charger.

- Sandpaper: Use sandpaper to prepare the wood surface for better conductivity.

- Safety equipment: It is crucial to prioritize safety. Wear gloves, safety goggles, and work in a well-ventilated area.

Step-by-Step Instructions

Now that we have our materials ready, let’s walk through the process of electrifying wood.

Preparation

Before starting, ensure you have a suitable workspace. Find a well-ventilated area where you can comfortably work. Once you’ve chosen your workspace, gather all the necessary materials and tools. Put on your safety gear, including gloves and goggles, to protect yourself during the process.

Surface Preparation

To achieve optimal conductivity, it’s important to prepare the wood surface. Start by cleaning the wood thoroughly, removing any dust, dirt, or debris. Next, use sandpaper to gently sand the surface of the wood. This step will create a smoother surface, allowing for better contact with the electrical charge.

Connection Setup

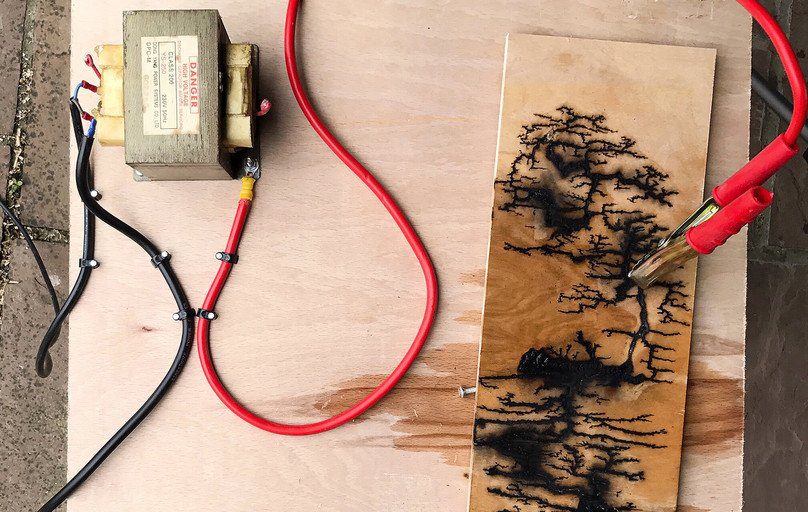

Now it’s time to set up the connections. Identify the positive and negative terminals of your battery charger. Attach the alligator clips to these terminals. One clip will be connected to the positive terminal, and the other to the negative terminal of the charger. Once the clips are securely attached, carefully connect them to the wood surface. Ensure that the clips make good contact with the wood.

Electrification Process

With everything set up, it’s time to initiate the electrification process. Turn on the battery charger and adjust the settings to a low voltage. Gradually increase the voltage while closely observing the wood’s reaction. You’ll notice that the wood starts to exhibit unique characteristics as it becomes electrified. The electrification process may take some time, so be patient and maintain a safe distance.

Safety Measures

Safety is paramount throughout the electrification process. Monitor the process closely, keeping an eye on the wood’s reaction and the charger’s performance. Never leave the charger unattended while it’s connected to the wood. After achieving the desired level of electrification, promptly disconnect the charger from the wood to ensure safety.

Tips and Troubleshooting

To ensure a successful electrification process, here are some tips to keep in mind:

- Experiment with different types of wood: Different types of wood may react differently to electrification. Try using various types of wood to observe the unique effects and conductivity levels.

- Start with low voltage: Begin with a low voltage setting on your battery charger and gradually increase it. This allows you to control the electrification process and prevent any potential damage to the wood.

- Observe and adjust: Pay close attention to the wood’s reaction as you increase the voltage. If you notice any signs of overheating or charring, reduce the voltage immediately. Adjust the settings to ensure a safe and controlled electrification process.

- Avoid excessive electrification: While it may be tempting to electrify the wood to the maximum extent, be cautious not to overdo it. Excessive electrification can lead to damage or compromise the structural integrity of the wood. Aim for the desired level of conductivity without going overboard.

- Troubleshooting common problems: If you encounter issues such as weak conductivity or inconsistent electrification, try sanding the wood surface again to enhance contact. You can also adjust the position of the alligator clips to improve the flow of electricity.

Applications of Electrified Wood

Electrified wood opens up a world of possibilities for various applications. Here are a few examples:

- Decorative purposes: Electrified wood can be used to create stunning decorative pieces. Imagine a wooden lamp with a soft, electrified glow or a wall panel with intricately electrified patterns. The unique blend of natural wood and electrification can add a captivating aesthetic to any space.

- Electric conductivity experiments: Electrified wood serves as an excellent medium for conducting electrical experiments. It allows you to study the behavior of electricity within a non-conductive material, opening doors to scientific exploration and innovation.

- Art and design projects: Artists and designers can leverage electrified wood to push the boundaries of creativity. Incorporate electrified wood into sculptures, installations, or furniture pieces to add an element of surprise and intrigue. The juxtaposition of organic wood and electrical currents can create visually striking and thought-provoking artwork.

Conclusion

Electrifying wood with a battery charger is a fascinating process that unlocks the hidden potential of this natural material. By following the step-by-step instructions and taking necessary safety precautions, you can experiment with electrified wood and explore its various applications. Whether for decorative purposes, scientific experiments, or artistic endeavors, electrified wood offers a unique and captivating way to blend nature with electricity. So, grab your materials, embark on this electrifying journey, and let your imagination run wild!

Additional Tips & Information

Enhancing Conductivity

While wood is not naturally conductive, there are techniques you can employ to enhance its conductivity for electrification. One approach is to use conductive coatings or additives. These substances contain conductive particles that can be applied to the wood surface, creating a conductive layer. Examples of conductive coatings include graphite-based paints or conductive epoxy resins. By utilizing these coatings, you can improve the wood’s ability to conduct electricity and enhance the electrification process.

Another method to enhance conductivity is by impregnating the wood with conductive additives. This involves treating the wood with substances like carbon nanotubes, metal nanoparticles, or conductive polymers. These additives can fill the pores of the wood and establish conductive pathways, allowing electricity to flow more easily through the material. However, it is important to note that the selection and application of such additives should be done carefully, considering the intended purpose and potential environmental impacts.

Safety Guidelines

Safety should always be a top priority when working with electricity and wood. Here are some essential safety guidelines to follow during the electrification process:

- Ensure a well-ventilated workspace: Work in a space with proper ventilation to prevent the accumulation of fumes or gases that may be emitted during the process.

- Use appropriate safety gear: Wear gloves to protect your hands from any potential electric shocks and goggles to shield your eyes from flying debris or splinters.

- Disconnect the charger before making adjustments: Before making any changes to the setup or adjusting the alligator clips, always disconnect the battery charger from the power source to avoid accidental shocks or short circuits.

- Avoid contact with water: Keep water or any other liquids away from the electrification setup to prevent the risk of electrical shocks.

- Be cautious with high voltages: If you’re working with higher voltage battery chargers, take extra precautions. High voltages can be dangerous, and it is important to understand the risks and use appropriate safety measures.

- Work in a stable environment: Ensure that your workspace is stable and free from clutter. This minimizes the chances of accidents and provides a safer environment for the electrification process.

- Stay vigilant: Keep a close eye on the wood and the battery charger throughout the process. Look out for any signs of overheating, smoke, or unusual behavior, and be prepared to act swiftly if necessary.

- Educate yourself on electrical safety: Familiarize yourself with basic electrical safety principles. Understand how to handle electrical equipment safely and learn about proper grounding techniques.

- Seek professional assistance if needed: If you are uncertain or uncomfortable with any aspect of the electrification process, it is advisable to seek guidance from a professional or experienced individual in the field.

- By adhering to these safety guidelines, you can minimize risks and ensure a secure working environment when electrifying wood.

Types of Battery Chargers

When it comes to electrifying wood, choosing the right type of battery charger is crucial. Here are a few common types of battery chargers to consider:

- Constant Voltage Chargers: These chargers provide a consistent voltage output, making them suitable for a range of applications. They maintain a steady voltage level and are often adjustable, allowing you to control the amount of electricity flowing into the wood.

- Smart Chargers: Smart chargers are designed with advanced technology to optimize the charging process. They can automatically detect the battery’s state and adjust the voltage and current accordingly. While primarily intended for battery charging, they can also be used effectively for electrifying wood.

- Pulse Chargers: Pulse chargers utilize a pulsing current to charge batteries. They deliver intermittent bursts of energy to the wood, which can enhance the electrification process. However, it is important to note that pulse chargers may require additional precautions and experimentation to ensure safe and effective electrification of wood.

- Variable Voltage Chargers: These chargers allow you to adjust the output voltage manually. They offer flexibility in controlling the intensity of the electrification process, making them suitable for experimenting with different wood types and desired conductivity levels.

- Solar Chargers: Solar chargers utilize solar panels to convert sunlight into electrical energy. While they are primarily designed for charging batteries using renewable energy, they can also be utilized for electrifying wood. Solar chargers offer the advantage of being environmentally friendly and portable, allowing you to work in outdoor settings.

When selecting a battery charger, consider its voltage range, adjustability, safety features, and compatibility with the electrification process. Consult the charger’s user manual or consult with professionals to ensure the charger meets the requirements for electrifying wood effectively and safely.

Wood Selection

The type of wood you choose for electrification can impact the results and conductivity. Here are some factors to consider when selecting wood for electrification:

- Wood Species: Different wood species have varying levels of natural conductivity. Experiment with various species to observe the conductivity and electrification effects. Hardwoods like oak or walnut generally exhibit better conductivity than softwoods like pine or cedar.

- Moisture Content: Wood with high moisture content may have higher resistance to electrical flow. It is recommended to use wood with lower moisture content for better conductivity. Allow the wood to dry adequately before starting the electrification process.

- Grain Orientation: The orientation of the wood grain can affect its conductivity. In general, electrifying wood perpendicular to the grain may yield better results as it allows for better flow of electricity along the grain fibers.

- Surface Condition: Ensure the wood surface is clean and smooth. Sand the surface gently to remove any roughness or contaminants, improving the contact between the wood and the alligator clips.

Remember that each wood species may react differently to electrification, and experimentation is key to understanding the specific characteristics and conductivity of different types of wood.

Advanced Electrification Techniques

While the basic electrification process involves using a battery charger, there are advanced techniques that can further expand the possibilities of electrifying wood. Here are a few advanced methods to consider:

- Electrolysis: Electrolysis involves immersing the wood in an electrolyte solution and passing an electric current through it. This process can promote the migration of ions and enhance the conductivity of the wood. However, caution must be exercised as electrolysis involves the use of chemicals and may require additional safety measures.

Creating Conductive Paths: For intricate electrification designs or complex projects, you can create conductive paths within the wood. This can be achieved by embedding conductive materials like metal wires or conductive paints into the wood. These pathways provide a controlled flow of electricity, resulting in unique electrification patterns and effects. - Carbonization: Carbonization involves subjecting wood to high temperatures in the absence of oxygen, which converts it into carbon. Carbonized wood exhibits improved conductivity due to the removal of volatile components. Carbonization can be achieved using techniques such as pyrolysis or laser engraving.

These advanced techniques require a deeper understanding of the principles involved and may involve more complex setups or additional equipment. Exercise caution and seek expert guidance when attempting advanced electrification techniques.

Frequently Asked Questions (FAQ)

Q: Can any type of wood be electrified?

A: While wood can be electrified, the conductivity levels may vary depending on the type of wood. Hardwoods generally exhibit better conductivity compared to softwoods. It is recommended to experiment with different wood species to observe the electrification effects and choose the most suitable wood for your desired outcome.

Q: Is electrified wood safe to touch?

A: Electrified wood should be approached with caution. While the voltage used in the electrification process is typically low, it is still important to exercise safety measures. Avoid touching electrified wood directly, especially when the electrification process is ongoing. Always disconnect the power source and follow appropriate safety guidelines to minimize the risk of electric shocks.

Q: How long does it take to electrify wood?

A: The time required to electrify wood can vary depending on several factors, such as the type of wood, moisture content, and the desired level of electrification. It is a gradual process that may take anywhere from a few minutes to several hours. It is recommended to monitor the electrification process closely and adjust the voltage gradually until the desired effect is achieved.

Q: Can electrified wood be used outdoors?

A: While electrified wood can be used outdoors, it is important to consider the environmental conditions and take appropriate measures to protect the electrification components. Exposure to moisture, extreme temperatures, and direct sunlight can impact the longevity and functionality of the electrified wood. Applying a protective coating and ensuring proper maintenance can help mitigate these effects.

Q: Can I reverse the electrification process?

A: The electrification process is not reversible, as it involves altering the conductivity of the wood through the introduction of an electrical charge. Once the wood is electrified, it retains its conductive properties. However, the intensity of the electrification effects can be controlled by adjusting the voltage during the process.

Q: Are there any risks associated with electrifying wood?

A: Working with electricity always carries inherent risks. It is important to prioritize safety throughout the electrification process. Risks include electric shocks, overheating, or damage to the wood. By following safety guidelines, wearing appropriate protective gear, and closely monitoring the process, you can minimize these risks and ensure a safe working environment.

Q: Can I combine electrified wood with other materials in my projects?

A: Absolutely! Electrified wood can be combined with various materials to create unique and captivating projects. Consider integrating other conductive materials, such as metals or conductive paints, to enhance the electrification effects or experiment with different design elements to achieve the desired aesthetic and functional outcome.

Q: Can electrified wood be used in DIY projects?

A: Yes, electrifying wood can be a fascinating and engaging DIY project. However, it is essential to have a good understanding of electrical safety, follow the outlined instructions, and exercise caution throughout the process. If you have any doubts or concerns, it is advisable to seek guidance from professionals or experienced individuals before attempting the electrification process on your own.

Q: What are some educational applications of electrified wood?

A: Electrified wood can serve as a valuable tool for educational purposes. It can be used to demonstrate the principles of conductivity, electrical circuits, and electrochemistry. Additionally, electrified wood can be utilized in science experiments or engineering projects, allowing students to explore the behavior of electricity in non-conductive materials.

About The Author

Pat Rowse is a thinker. He loves delving into Twitter to find the latest scholarly debates and then analyzing them from every possible perspective. He's an introvert who really enjoys spending time alone reading about history and influential people. Pat also has a deep love of the internet and all things digital; she considers himself an amateur internet maven. When he's not buried in a book or online, he can be found hardcore analyzing anything and everything that comes his way.