There are many ways to sharpen a core drill bit. The best way is to buy a Bench grinder or belt sander, or invest in a specialized drill bit sharpener. However, if you have no time or patience to grind drill bits by hand, you can use an electric bench grinder. This machine will hold the drill bit firmly in the core and rotate it on all sides. After grinding, cool the core bit off and repeat the process if needed.

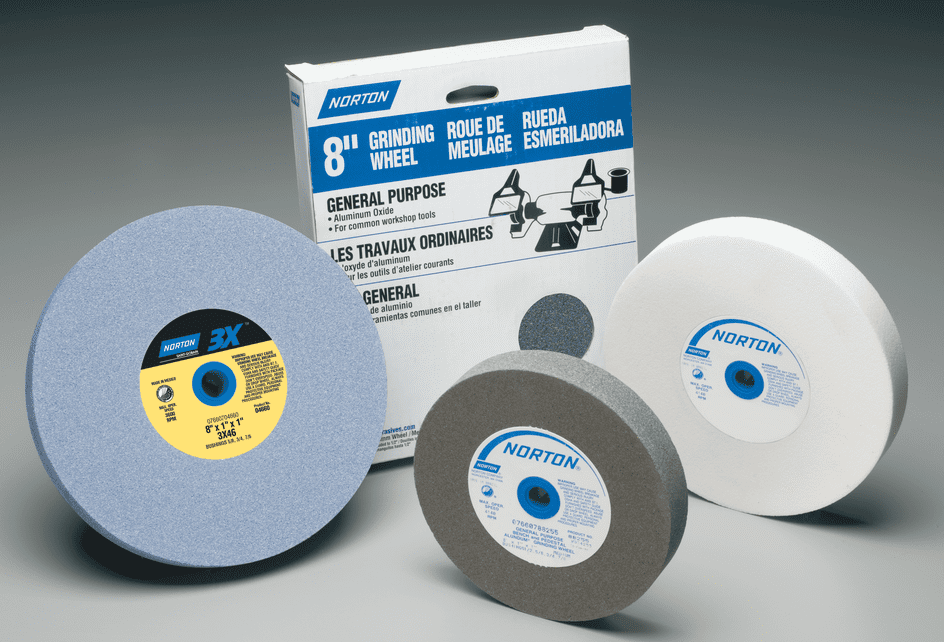

Bench grinder

The first step in sharpening a core drill bit with a bench grinder is to set up the tool. Before starting, prepare the drill bit and hold it in both of your hands. Hold it at a 60-degree angle to the belt sander’s wheel, with its cutting edge touching the grinding wheel. Move the drill bit slowly to the center of the wheel without rotating it. Make sure to keep the bit at the same angle as the factory angle of 60 degrees.

After you’ve assembled the equipment, attach a side wheel to the grinder. The drill bit should be at least an eighth of an inch in diameter. Some drill bits have multiple facets. You can use a bench grinder’s side wheel to sharpen a variety of drill bits, from wood to 1/8 inch diameter. One popular model is the Woodstock D4144. A bench grinder’s manual is available online, so you can check if it is right for you before you start sharpening. Make sure you have ample space on the bench and a stand where you can fix the jig.

For cobalt chromium split drill bits, you may have a problem sharpening the chisel yourself. Since the chisel is made of hard steel, it’s unlikely to be sharpened by hand. A machine is needed to cut the chisel to a smaller size. Not relieving the chisel will result in chipping or dulling of the drill bit. The process of sharpening a core drill bit will help you save time and money in the future.

The angle of the drill bit against the grinding wheel is usually forty-five degrees. The angle should be steep enough to remove the dull surface of the bit without wearing it down. If the angle is too shallow, the drill bit will not bore smoothly. Once you’ve determined the angle, you can proceed to sharpening it using the bench grinder. There are two main steps in sharpening a core drill bit.

While you can sharpen any drill bit using a bench grinder, you should use a jig for a better and more efficient result. The jig will hold the drill bit at a proper angle for grinding. Ensure that you are not operating a grinder that’s too hot or you’ll damage the drill bit. You should keep a safety guard on the bench grinder to avoid accidental injury.

If you’re sharpening a core drill bit with a bench grinder, you must first determine which part needs to be cut. Then, measure the length of the drill bit and mark the area where the cutting edge is located. You must be able to see the line where the cutting edge intersects the landing. A small amount of angle is necessary for the tip to not chip. Then, set up the bit in the vice.

Belt sander

You can easily sharpen a core drill bit using a belt sander by following a few simple steps. The first step is to remove the bit from the drill chuck. It’s essential to keep the bit out of the drill chuck when sharpening it so that you don’t damage it by accidentally slipping it. The next step is to sharpen the bit’s face.

To start, make sure you have a comfortable position and hold the bit in both hands. Hold the drill bit at about 60 degrees to the belt sander. You want the end of the bit to land against the belt. Start with the high points of the sample and work your way down. Avoid the edge of the sample as this will cause the bit to flick. Use a hand-planer for the softer wood.

Once you have the drill bit on the belt sander, you can start sharpening it by tilting it 45 degrees from the tip. While doing this, make sure to clamp down the vice on the drill bit. Once you have the bit properly angled, you can begin sharpening it. Remember to rotate the drill bit counterclockwise to give it a rounded edge.

Dedicated drill bit sharpener

If you want to get the best possible results from your drilling projects, consider purchasing a specialized drill bit sharpener. There are several types of drill bits and different angled tips. A specialized tool is needed to sharpen split point or core drill bits. You should first determine what kind of drill bit you have, and then purchase the sharpening tool. Once you have found the right one, use it regularly to keep it sharp.

A specialized core drill bit sharpener is essential if you are looking for the best possible results. While core drill bits are similar to other bits, their design and materials may be different. Therefore, you should be able to sharpen your core drill bit without having to buy a new one. NCCuttingtools is an effective tool for sharpening all kinds of drill bits.

Using a specialized core drill bit sharpener can save you money and time. It also helps you to maintain your drill bits without having to spend a lot of money on a new one. A dedicated drill bit sharpener is an excellent investment for a home or professional business. It saves you a lot of money and time, and is worth the cost. A dedicated drill bit sharpener will also allow you to use the same drill bit in multiple projects.

You can find a dedicated drill bit sharpener online or in a local hardware store. There are many types of drill bits, and some of them are made of premium high-speed steel. They are designed for heavy-duty use in steel and iron. So, if you want the best results, you’ll need a sharp bit sharpener. However, you can find some great deals online, so you should consider buying one today. You’ll be glad you did.

The first step in the sharpening process is to make sure the drill bit is longer than the surface thickness of the working surface. The length of the drill bit should be about 2 inches longer than the surface thickness of the material. Then, you can drill until the guide bit pokes out the other side. To avoid any risk of damaging the core, your partner should tell you when the guide bit has peeled out and stop drilling.

When sharpening your drill bit, it is crucial to understand how to use it properly. For example, a guide bit should be horizontal on walls and vertical on floors. Misalignments will cause the surface to tilt, which is not desirable. Secondly, you should know the exact depth of the drill bit. You can use a single pass or multiple passes to reach the desired depth.

About The Author

Mindy Vu is a part time shoe model and professional mum. She loves to cook and has been proclaimed the best cook in the world by her friends and family. She adores her pet dog Twinkie, and is happily married to her books.