Last Updated on September 16, 2022

When did plastic zippers start being used? They were first used in Elsa Schiaparelli’s winter collection in 1935. Their manufacturing process is fairly simple. Plastic wire is wound onto two alternating spools and held in place with cotton tape. They are a great addition to any wardrobe and will save you countless hours of sewing. In 1935, a manufacturing machine was invented that made plastic zippers.

Elsa Schiaparelli’s 1935 winter collection was the first to use plastic zippers

Plastic zippers are an excellent way to make garments more durable, while at the same time reducing the number of seams and creases. Schiaparelli used plastic zippers in her 1935 winter collection to create a seamless transition between day and night. Her outfits were designed to transition from day to night and were often made with synthetic fabrics. She was a perfectionist and pioneered many innovations, including a see-through raincoat and ladies’ evening jacket.

She had an unusual childhood, and disliked being reprimanded by her parents. This resulted in a lifelong interest in the solar system and the stars. Her father was an astronomer, and he named the craters on Mars and the moon. He also pointed out Elsa’s moles, including Ursa Major, the Big Dipper.

Plastic zippers were introduced in the 1930s. In fact, Schiaparelli’s 1935 winter collection was the first to use them. This was because of her dedication to the worldly woman. She was inspired by the heavenly constellations and even incorporated them into her designs. And Schiaparelli’s designs were so popular that Lord & Taylor’s buyer ordered 40 copies of her iconic bowknot sweater.

After World War II, Elsa Schiaparelli worked with Surrealist artists and incorporated their work into her designs. She influenced artists such as Marcel Duchamp, Francis Picabia, and Alberto Giacometti in their work. She also influenced Yves Saint Laurent and Yves Saint-Laurent.

The designs were often subversive and featured a combination of unattractive and attractive elements. For example, her infamous Tear Dress featured pieces of fabric that were torn from the fabric, revealing a pink lining underneath. A matching veil featured loose pieces of fabric. The dress’s aesthetic was inspired by Dali paintings, and it’s important to note Schiaparelli’s collaboration with Dali.

The zipper, also known as a slide fastener, was not used in fashion until 1935. Schiaparelli’s 1935 winter collection was the first to use plastic zippers. Unlike most zippers, the plastic zippers were not hidden. It became an important design element of the garment, and it was widely viewed as avant-garde.

Sundback invented the first manufacturing machine to produce them

Before the invention of hookless fasteners, clothing, bags, and suitcases were closed with buttons, buckles, and pins. Some required help from another person to close. Sales of this new product were promising but slow, so the Universal Fastener Company hired electrical engineer Gideon Sundback to improve the production process. Sundback had studied electrical engineering in Germany and came to the U.S. with a dream of making a better zipper.

Gideon Sundback, an electrical engineer by training, designed the first plastic zipper in 1913. He was working at the Universal Fastener Company, and he married the daughter of the plant manager. His wife died in 1911, but he kept busy designing and improving the Judson C-curity Fastener. When his wife died in 1911, he was able to focus on the new invention and made it into a working prototype.

After Judson had patented his invention, he worked with Sundbeck to make plastic zippers. He invented a new machine to produce the fastener. The new machine cut scoops out of wire and punched dimples to create the teeth. The Universal Fastener Company produced hundreds of feet per day within its first year of operation. By the 1920s, zippers were being used for galoshes and other clothing items. In 1923, industrialist B. F. Goodrich patented the zipper name and trademarked its use.

During the early days of the new millennium, zippers were available in hundreds of colors and styles. Gideon Sundback’s machine allowed for both ends of a jacket to be opened. The zipper design was improved over the years and it became a standard in clothing. The zipper was eventually adopted for use in space suits. By the end of the century, Americans had caught up and the number of zipper sales reached a billion.

In 1913, Gideon Sundback showed the prototype of a new design to Walker. Then he improved on the original Hookless design by changing the fastener elements into small interlocking scoops. These scoops fit tightly together when connected by a slide, and separate easily when separated. It’s a non-obvious design, but this invention paved the way for the modern zipper.

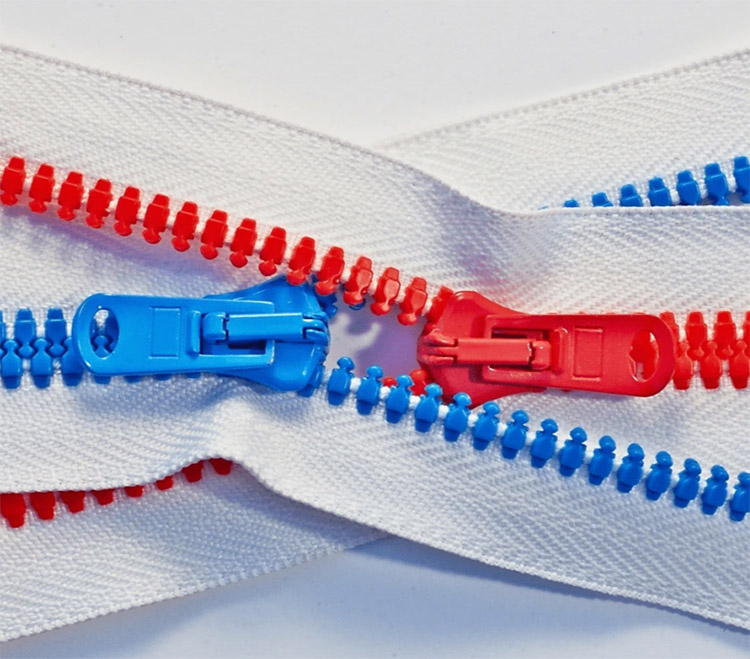

They are made by winding a plastic wire onto alternating spools

The simplest form of a plastic zipper is the spiral, but there are also teethed and ladder versions, and even ones woven directly into fabric. Plastic zipper stringers are manufactured by winding plastic wire onto alternating spools with a molding process that is similar to the production of metal zippers. To form a spiral, a plastic wire is fed into a mold that contains small, flattened teeth shaped like a U. Two cords run through the mold and the plastic wire is heated. Once it has hardened, the wire is then passed through a folding machine to create the U-shape teeth of a zipper. These teeth are then sewed to a cloth tape or other suitable surface for sewing.

A metal zipper is made in the same way, but it is much more expensive than plastic zippers. In addition to plastic zippers being more expensive than metal zippers, they also take a longer time to produce. In addition to the labor-intensive manufacturing process, zippers are not easy to wear because they may fall off a zipper. Instead, you should avoid them by carefully separating them before using them.

The process of making zippers is a complex one. Unlike metal zippers, plastic zippers are manufactured using plastic heat. The process is complex, but it is possible to manufacture them on a large scale. The process of winding plastic wire onto alternating spools is a simple, yet effective method. However, the process is time-consuming, and it is difficult to produce small quantities of plastic zippers.

There are several types of plastic zippers. The first was known as a snap, and it was widely adopted during the 1950s. After that, the zipper became the standard fastener for clothing. A zipper’s versatility made it a popular choice. The zipper’s versatility was not surpassed until the early 2000s, when it was adopted for military and medical applications.

They are held tightly by a cotton tape

A cotton tape is applied around a zipper to help it stay closed. A strong cotton tape reinforced with nylon is then applied to the ends of the zipper. This prevents it from fraying. The tape also helps keep the zipper from slipping. A cotton tape helps keep the zipper closed and keeps the zipper from tearing. To prevent the tape from fraying, make sure to cut it at a slight angle.

The invention of the zipper didn’t come from an American company. Within a few years of its introduction, British manufacturers sought to produce them. French and German suppliers followed in the mid-1920s. Britain’s chief manufacturer was the Lightning Fastener Company, which later gave the zipper its name. Its success made it a global sensation and helped to make clothing of all types and materials. Cotton tapes are held tightly in place by a cotton tape.

Plastic zippers can be made from plastic or metal. The process to make them is the same for both. Plastic zippers have a cotton tape that is held in place by a metal slider. A cotton tape will hold the zipper closed. Cotton tapes are more durable than nylon ones. You can even use nylon tape to secure zippers. In addition to cotton tapes, plastic zippers also feature a nylon zipper.

To manufacture plastic zippers, a molding process is used. It’s similar to making metal zippers. The plastic is heated between two screw cylinders that form the loops. A head maker then forms a round knob at the center of the loops. This process holds the plastic stringer in place while it cools. The plastic stringers are sewn onto a cloth tape.

About The Author

Fernánda Esteban is a food fanatic. She can't go more than a few hours without eating, and she loves trying new foods from all over the world. Her friends know that they can always count on her for a good conversation, and she's an animal lover who will never turn down an opportunity to pet a dog or cat. Fernánda also enjoys learning about random facts, and she's a social media practitioner who loves to share what she knows with others.